Silicon Production by Country 2026

- The production data for 2022 and 2023 represent the sum of Ferrosilicone Production and Silicon Metal Production.

- All data measured in thousands of metric tons. Also known as a tonne, one metric ton = 1,000 kg, or roughly 2,204.6 lbs.

- Additional countries not listed below produced lesser amounts of silicon, with collective total production of 180 thousand metric tons in 2023, 223 thousand metric tons in 2022, and 128 thousand metric tons in 2021.

- Recent production figures for the United States are withheld or unavailable due to confidentiality or other reasons.

Silicon is a brittle, crystalline chemical element with a metallic, bluish appearance. It is considered a metalloid, meaning it possesses both metal and non-metal properties.

After oxygen, silicon is also the second-most plentiful element found within the earth’s crust, and it’s a critical part of numerous industries, including electronics and construction. Among other products, silicon is used to make computer chips, glass, ceramics, kitchen utensils, concrete, and enamel.

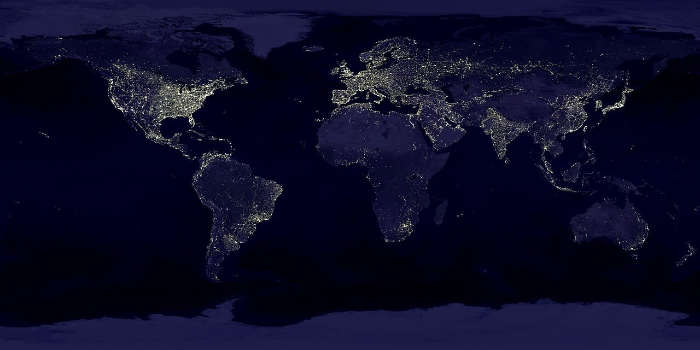

However, the production of silicon varies from country to country. Here’s a look at the world’s top silicon producers, as well as a brief glimpse at some key factors that can influence silicon production.

Top 10 Silicon-Producing Countries

Other key silicon-producing countries include but are not limited to Spain, India, Poland, Australia, Ukraine, and Canada.

China is the current world leader by a landslide thanks to its robust quartz preserves and well-run infrastructure. Those two factors combined allow China to not only produce vast quantities of silicon but to sell it at competitive prices to nations around the world.

Meanwhile, the United States has an edge when it comes to the overall silicon production landscape. This is especially the case when it comes to the type of top-tier silicon needed for products like semiconductors.

Additional Factors Impacting Silicon Production

Although silicon is a fairly abundant resource, its stores are not equally distributed around the globe. Countries (like China) with higher quartz reserves will have a natural edge over other players in the silicon production game. However, factors like the following can influence a country’s overall silicon production capabilities, as well.

Industrial Infrastructure

The better a country’s infrastructure when it comes to capabilities like mining, processing, and manufacturing silicon, the more cost-effectively it can produce a market-ready product at scale.

Energy Access

Ample, reliable sources of energy are essential in order for a country to be able to produce silicon efficiently, as energy-intensive electric arc furnaces are required for the quartz-smelting process.

Labor Access

Efficient production of high-quality silicon from start to finish requires access to labor that’s uniquely qualified for the job. The more trained, qualified workers available, the better the country’s likelihood of succeeding in silicon production.